BICSc Colour-coding

Are you following the recommended colour chart for the cleaning industry?

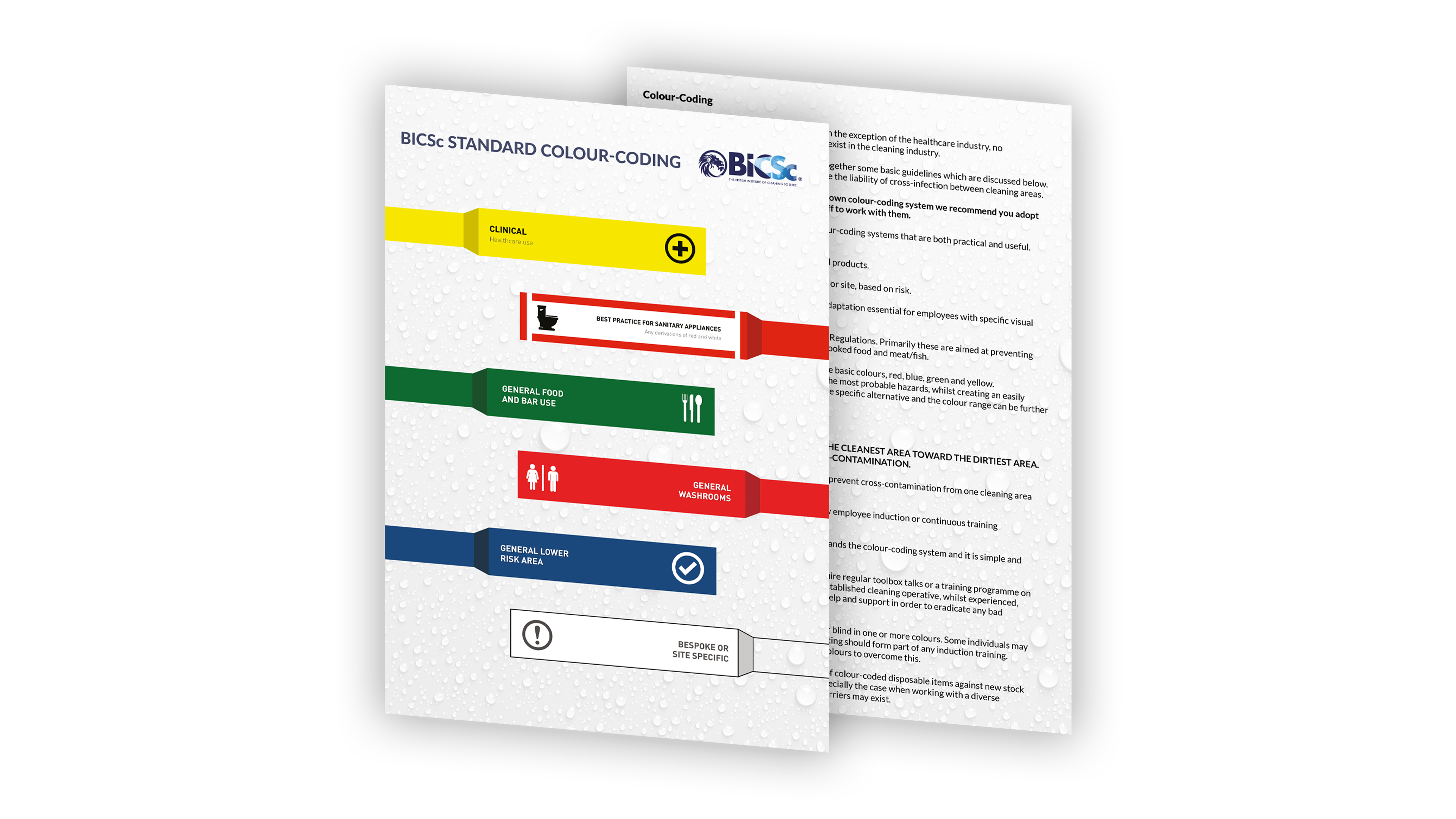

Colour-coding

Colour-coding can be a complex subject and with the exception of the healthcare industry, no national or international compulsory standards exist in the cleaning industry.

To help overcome this problem, BICSc has put together some basic guidelines which are discussed below.

This guidance aims to raise standards and reduce the liability of cross-infection between cleaning areas.

If your company has not already introduced its own colour-coding system we recommend you adopt these BICSc guidelines and encourage your staff to work with them.

Some cleaning companies operate bespoke colour-coding systems that are both practical and useful.

They include systems that:

1. Isolate particular medical and industrial products.

2. Designate particular areas of a building or site, based on risk.

3. Are the judgment of local policy or an adaptation essential for employees with specific visual impairments.

4. Comply with the current Food Hygiene Regulations. Primarily these are aimed at preventing cross-contamination between cooked/uncooked food and meat/fish.

Colour-coding systems generally make use of the basic colours, red, blue, green and yellow.

Generally, these colours are sufficient to cover the most probable hazards, whilst creating an easily understood system. White may be added as a site specific alternative and the colour range can be further extended with the use of striped cloths.

Colour-Code Guidelines

THE GOLDEN RULE: ALWAYS WORK FROM THE CLEANEST AREA TOWARD THE DIRTIEST AREA. THIS GREATLY REDUCES THE RISK OF CROSS-CONTAMINATION.

1. The aim of a colour-coding system is to prevent cross-contamination from one cleaning area or surface to another.

2. It is vital that a system forms part of any employee induction or continuous training programme.

3. It is imperative that staff easily understands the colour-coding system and it is simple and effective to use.

4. The novice cleaning operative may require regular toolbox talks or a training programme on the fundamental issues for concern. The established cleaning operative, whilst experienced, may have entrenched habits that require help and support in order to eradicate any bad practice.

5. A sizeable minority of people are colour blind in one or more colours. Some individuals may not know this and colour identification testing should form part of any induction training.

Sometimes, a number system is linked to colours to overcome this.

6. Monitoring of the system, and control of colour-coded disposable items against new stock release, is extremely important. This is especially the case when working with a diverse workforce, where literacy and language barriers may exist.

Contact

Fill out the following form if you wish to be contacted by our team.

For a quicker response please call us on

+44 (0)1604 678710

office hours

MON-FRI 09:00 - 17:00

Contact Us

9 Premier Court

Boarden Close

Moulton Park

Northampton

NN3 6LF

Email: [email protected]

Tel: +44 (0)1604 678710

© BICSc 2024

Policy Documents | The British Institute of Cleaning Science

All Rights Reserved | Company Reg 1524014